Demin2030

Within the Demin2030 project, improvements are being explored for existing and new process water factories of Evides Industriewater. The objective is to find the demi water purification concept of the future.

Contact usThe demi water purification concept of the future.

All kinds of research is needed to find the demi water purification concept of the future. Within the Demin2030 project, innovation is mainly sought in the 'desalination' sub-process, by applying new separation techniques and combining existing techniques in new ways (hybrid solutions).

What is the problem

Fresh, demineralized water is of great importance to the chemical industry, because it is used in all kinds of chemical processes (for example for cooling or the production of steam). A high and constant quality of the demineralised water is important for the continuity of the business processes in the industry.

In the Demin2030 project, research is conducted into demineralized water production of the future, with the aim of applying the researched concepts within 5- to 10 years. Among other things, the situation of Dow Terneuzen is being examined. By using a higher water quality, water use becomes more efficient because it is easier to reuse and wastewater is limited.

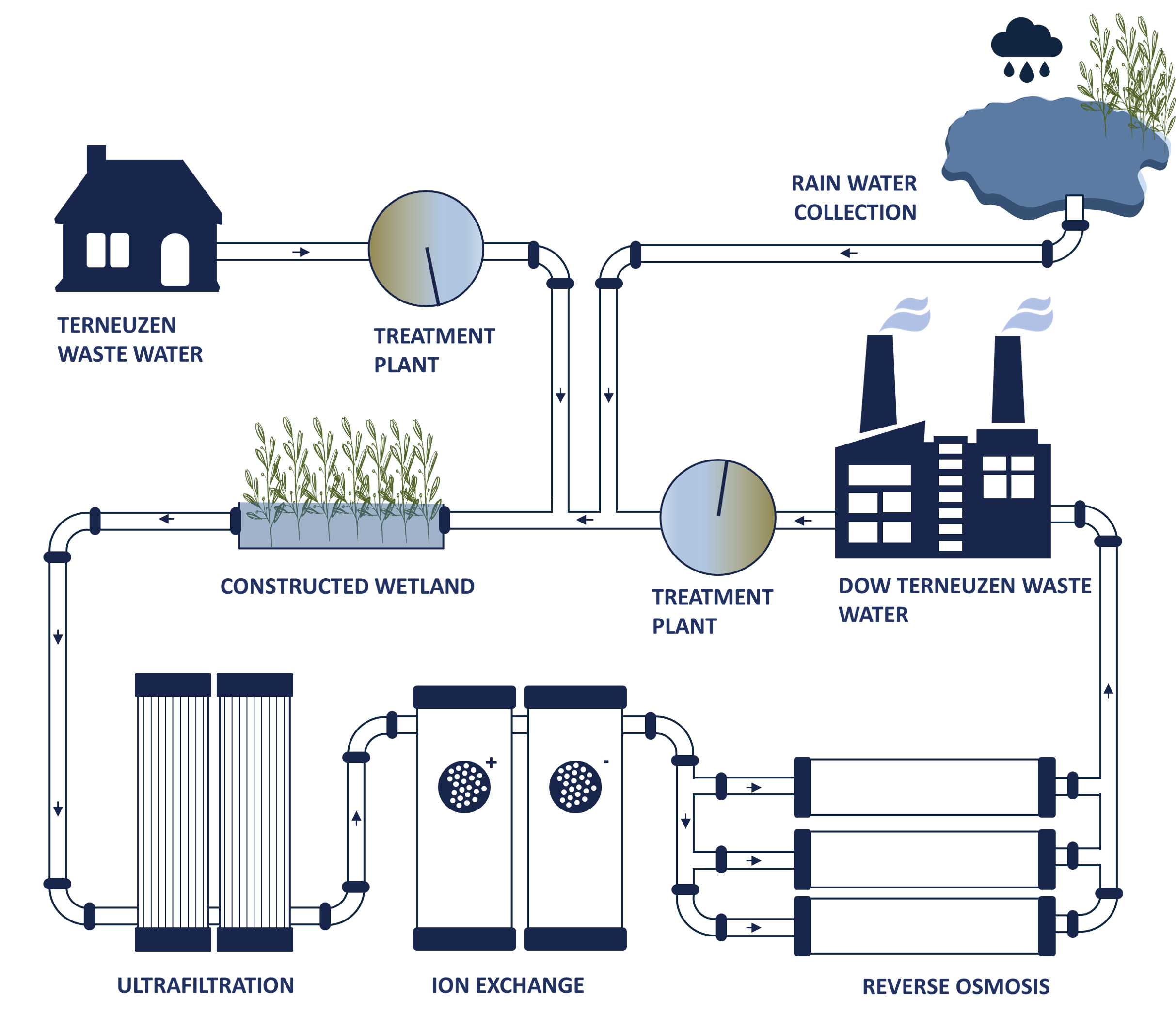

By switching to local water sources, such as WWTP effluent from the city of Terneuzen and from Dow, and by optimizing the desalination process, work is being done on a water efficient design of water use. This is what the Demin2030 research is all about: improving the demi water treatment concept of the future in terms of water quality, water footprint, total cost of ownership, sustainability and reliability.

Research

A two-year pilot project that conducts research into the reuse of waste water from the chemical factory and WWTP effluent from the city of Terneuzen. The intended future factory has been recreated in miniature. In this mini-factory, the water is treated by a succession of new and existing techniques. First, the water is sent through a hybrid wetland to reduce the organic load on the subsequent membrane processes. Then the water goes through an ultrafiltration (UF) installation to remove the larger particles from the water. Finally, the water is desalinated using ion exchange (IX) and reverse osmosis (RO). The saline waste stream from the reverse osmosis step, the concentrate, is then reused in backwashing the UF and regenerating the IX.

Results

We are currently in the final phase of the project and the reuse of the RO concentrate is being tested by UF and IX. In the meantime, with the help of the achieved pilot results, the final considerations are also being made for the design of the full-scale factory that will be taken into use in 2025.